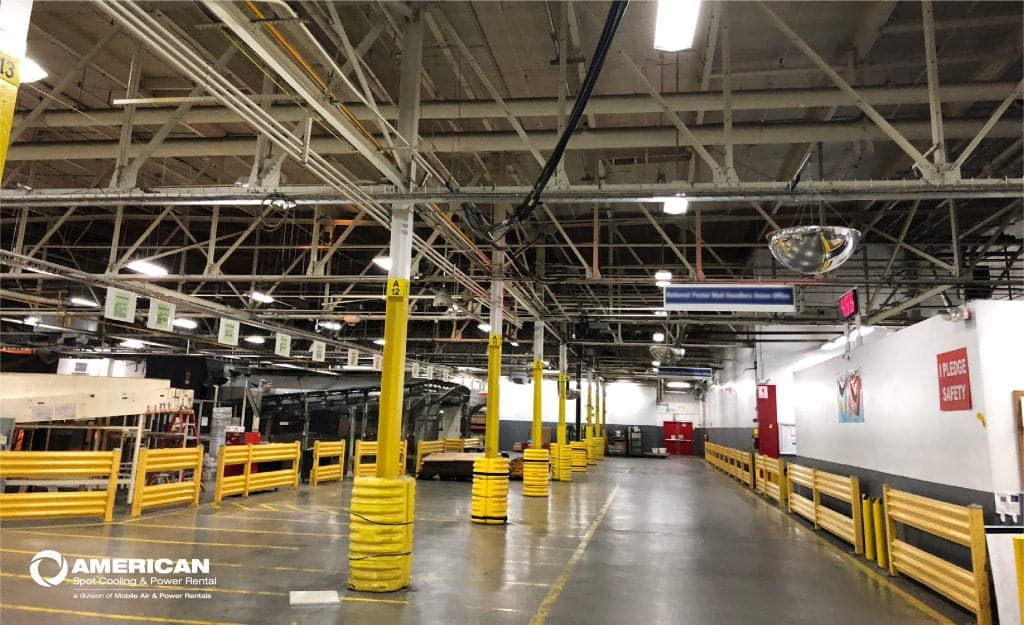

When temperatures drop, construction projects face serious obstacles. Concrete won’t cure properly below 40°F. Mortar freezes and adhesives fail. Workers struggle to stay productive when they’re fighting the cold. A reliable temporary heating rental keeps your project on schedule while protecting your crew and materials from harsh conditions.

Winter doesn’t have to mean shutdowns and delays. The right jobsite heating solutions let you maintain quality work through the coldest months, avoiding costly weather-related setbacks.

Common Winter Challenges: Frozen Materials, Worker Safety, Downtime

On active job sites, cold weather causes a number of issues. When temperatures drop, materials respond differently. The paint is not drying, and the caulk won’t set. Curing drywall compound takes an eternity, and other critical materials freeze. Your timetable is affected by these delays, which cause subsequent trades to be delayed and project timescales to be extended.

Frozen ground complicates excavation work. Water lines and hoses freeze. The equipment runs poorly or refuses to start. Each of these issues costs time and money, making cold weather construction more expensive and complicated than summer work.

When teams encounter frigid conditions, worker safety also becomes an urgent concern. People are at risk for cold stress injuries like frostbite and hypothermia. When employees take frequent warm-up pauses, productivity declines. For the protection of construction workers during winter operations, the Occupational Safety and Health Administration offers specific guidelines.

Temporary Heating Options: Direct-Fired, Indirect-Fired, Hydronic Systems

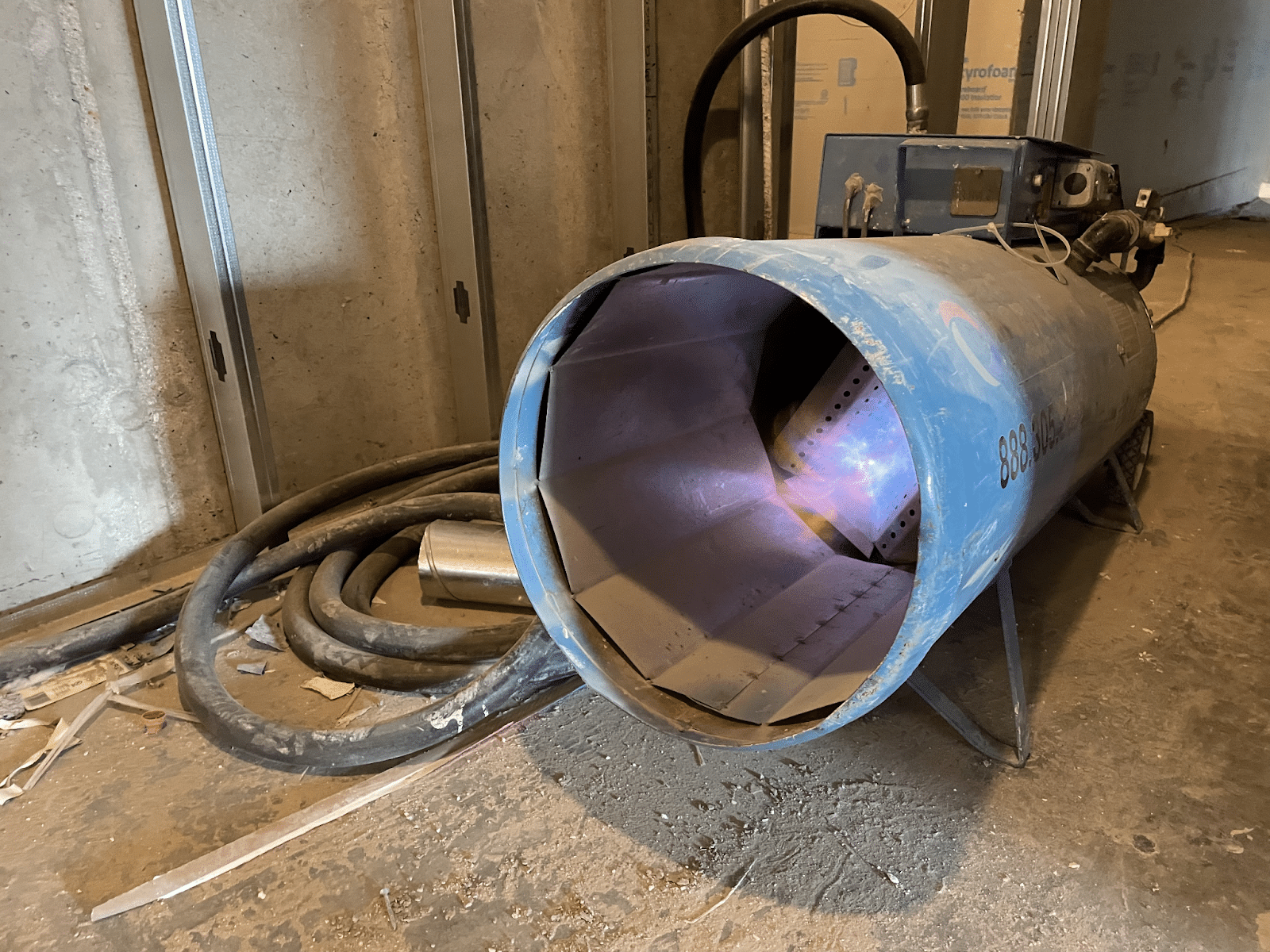

Different heating systems serve different purposes on construction sites. Direct-fired heaters burn fuel and release exhaust directly into the workspace. These units deliver maximum BTU output and work well for open areas where ventilation isn’t an issue. They’re popular for winter jobsite heating because they heat spaces quickly.

Indirect-fired heaters separate combustion from heated air. They produce clean, dry heat without fumes, making them suitable for enclosed spaces where workers spend extended time. These units cost more but provide safer air quality for occupied areas.

Hydronic systems circulate hot water through pipes or tubing. They’re ideal for concrete curing and ground thawing. Some projects use them to heat formwork or maintain specific temperatures for specialty materials. Mobile Air & Power Rentals offers industrial heater rentals suited to different applications.

Propane heaters for construction provide flexibility since propane is readily available and portable. Electric heaters work where power infrastructure exists, though they typically produce less heat output than fuel-burning alternatives.

Choosing the Right Size and Fuel Type for Your Site

Sizing a construction site heater requires calculating the cubic footage of your space and accounting for insulation levels, ceiling height, and outside temperatures. Equipment that is too small operates continuously without reaching the desired temperature. In addition to wasting fuel, oversized units produce uncomfortable hot areas.

Fuel selection depends on site conditions. Propane offers portability and doesn’t require electrical hookups. In areas with gas connections, natural gas is less expensive per BTU. For remote areas, diesel may be more suitable. Electric heaters make sense for cramped, smaller areas with an adequate power source.

When choosing temporary heating solutions, keep your project timeframe in mind. Equipment that is easily available but less efficient may be justified for short-term purposes. More advanced technologies that lower ongoing fuel costs are advantageous for longer projects.

The team at Mobile Air & Power Rentals can help match equipment to your specific requirements and recommend appropriate portable power rentals if needed.

Safety and Ventilation Best Practices

Keep in mind, every heating system requires proper ventilation. Carbon monoxide from combustion equipment can build to dangerous levels in enclosed spaces. Heaters should be kept away from combustible materials while adhering to manufacturer-specified clearances. Equipment meant for outside use should never be used inside buildings.

Regularly check units for damage or malfunctions. Look for leaks in the gasoline connections. Keep extinguishers on hand. Teach employees how to spot indications of cold stress and carbon monoxide poisoning.

In areas that are heated, install carbon monoxide detectors. Even when heating enclosed spaces, make sure there is enough fresh air exchange. Having a responsive rental partner enables you to quickly uphold safety standards when you need emergency heating rentals.

Cost and Efficiency Considerations

The size, type, and length of the heater all affect the rental price. While bigger industrial units cost more, a portable construction heater may cost between $200 and $500 each week. Fuel use contributes significantly to ongoing costs, particularly during protracted cold snaps.

Insulating your workspace reduces heating costs significantly. Temporary walls, plastic sheeting, and enclosed work zones help contain heat. Operating heaters only when needed rather than running them continuously saves money without sacrificing productivity.

Contact Mobile Air & Power Rentals for same-day heater delivery, and check out our case studies to see how other contractors have solved similar heating challenges.